Pivot International Acquires Digital Concepts

December 17, 2020Pivot International Acquires Digital Concepts Pivot Acquisition of Digital Concepts Pivot International, a technology engineering and manufacturing firm based in the Kansas City area, with 50+ years of experience in the fitness industry, has acquired Digital Concepts, the design, engineering, More…

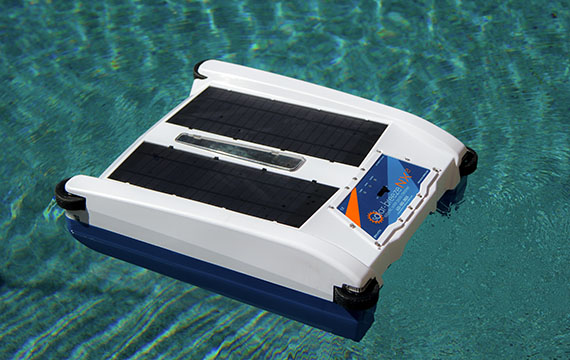

Pivot International Acquires Solar Pool Technologies

June 24, 2020Pivot International Acquires Solar Pool Technologies Pivot continues to expand its consumer-products portfolio and enhance its consumer-market position with the acquisition of Phoenix Arizona-based Solar Pool Technologies, a leader in solar-powered robotic swimming pool skimmers. Visit the Pivot International blog More…

Pivot International Acquires Castle Creations

October 23, 2019Pivot International Acquires Castle Creations Our parent company, Pivot International, has entered the electronic speed control and brushless DC motor retail markets with its acquiring the assets of Castle Creations. The company is based in the greater Kansas City area, More…

Pivot International Acquires A2E Limited

August 14, 2019Pivot International Acquires A2E Limited Pivot International acquires A2E Limited to expand its global capabilities for electronics hardware and software design services as well as manufacturing capabilities. A2E Limited, based in Livingston in the Edinburgh, Scotland region is an award-winning More…

Surface Mount Technology (SMT)

April 24, 2019Surface Mount Technology (SMT) Pivot International has expanded its manufacturing capacity with a strategic investment in Surface Mount Technology (SMT) to secure its position as an industry leader in the designing, engineering and manufacturing of electronics industry in the US More…